Electricity is an essential part of modern life, and it is used in almost every aspect of our lives. However, it can also be extremely hazardous if proper safety measures are not taken. Electrical hazards can cause serious injuries, burns, and even death. In this article, we will discuss electrical hazards, their causes, and control measures that can be taken to ensure electrical safety.

Electrical Hazards

Electrical Shock

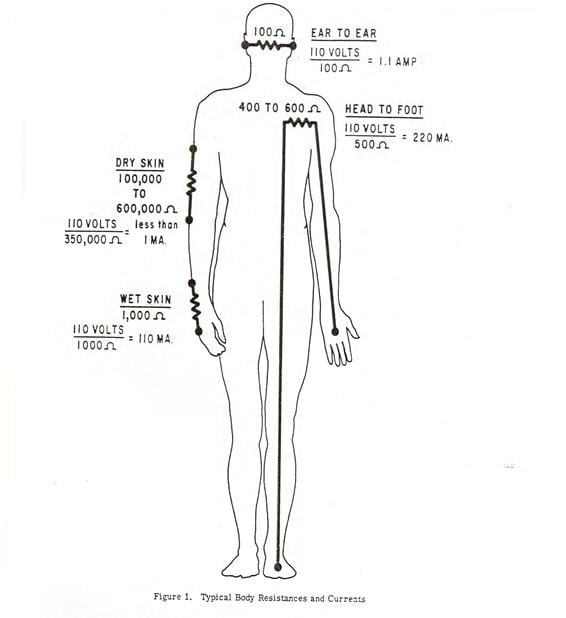

Electrical shock is the most common electrical hazard and can be caused by direct contact with live electrical conductors, or when a person comes into contact with an energized surface or object. The severity of the shock can vary depending on the amount of current and the duration of exposure. Electrical shock can lead to burns, muscle contractions, and even cardiac arrest.

Electrical Burns

Electrical burns are caused by electrical energy passing through the body and can occur when a person comes into contact with an electrical conductor or when there is a flashover or arc that produces intense heat. Electrical burns can be severe and can cause significant damage to the skin and tissues.

Electrical Fires

Electrical fires can occur when electrical equipment or wiring overheats and ignites surrounding materials. Electrical fires can be caused by overloaded circuits, damaged wiring, or faulty electrical equipment. Electrical fires can spread quickly and can be difficult to extinguish.

Causes of Electrical Hazards

- Faulty or damaged wiring or equipment: This is a common cause of electrical hazards. Electrical wiring and equipment can get damaged due to various reasons, such as wear and tear, exposure to the elements, or physical damage.

- Loose connections: Loose connections can lead to overheating and arcing, which can cause electrical fires and shock hazards.

- Use of poor quality fittings: Poor quality fittings, such as plugs and sockets, can increase the risk of electrical hazards. These fittings may not be able to handle the electrical load, leading to overheating and other hazards.

- Lack of earthing/bonding and grounding: Earthing/bonding and grounding are essential for electrical safety. Without proper earthing and grounding, electrical equipment and systems can become energized, leading to shock hazards.

- Use of overrated fuse or jumper: Overrated fuses and jumpers can lead to overloading of electrical equipment and systems, which can cause overheating, arcing, and electrical fires.

- Working on live equipment: Working on live equipment is one of the most dangerous causes of electrical hazards. It increases the risk of electric shock and can be fatal.

- Overloading of power sockets and equipment: Overloading of power sockets and equipment can cause overheating and increase the risk of electrical fires.

- Poor housekeeping: Poor housekeeping, such as cluttered workspaces and blocked electrical panels, can increase the risk of electrical hazards.

- Handling of electrical equipment with an incompetent person and lack of training awareness: Improper handling of electrical equipment and lack of training awareness can lead to accidents and injuries.

- Lack of safe working procedures and communication: Lack of safe working procedures and communication can increase the risk of electrical hazards. It is essential to have clear procedures and effective communication to ensure electrical safety.

- Failure to use appropriate PPE: Failure to use appropriate PPE, such as insulated gloves and safety glasses, can increase the risk of electrical hazards.

Electrical Safety Control Measures

To ensure electrical safety, several control measures can be taken. Here are some of the most effective electrical safety control measures:

A competent and experienced person shall be allowed to do electrical jobs

The first and foremost important aspect of electrical safety is ensuring that only competent and experienced individuals should be allowed to perform electrical jobs. Electrical work requires specific knowledge, skills, and experience to perform safely. A competent person is someone who has acquired the necessary training, education, and experience to do the job safely and efficiently. This person must also be aware of electrical hazards and how to prevent them.

It is the employer’s responsibility to ensure that their workers are competent and trained. Training and certification programs can be used to ensure that workers have the necessary knowledge and skills to perform electrical work safely. Employers can also verify their employees’ training, education, and experience before allowing them to work on electrical equipment.

Don’t work on live equipment, isolation and multi lock system shall be followed

Working on live electrical equipment can be extremely dangerous and can result in electric shock, injury, or death. Therefore, it is crucial to follow the isolation and multi-lock system to prevent injury by accidental energizing of equipment while it is attended by different crafts.

The isolation and multi-lock system involve disconnecting the equipment from its energy source, locking the disconnect in the off position, and placing a tag on the equipment to indicate that work is being performed. This system ensures that the equipment cannot be inadvertently energized while maintenance or repair work is being carried out.

A multi-lock system is used to prevent injury by accidental energizing of equipment while it is attended by different craft. The executing authority and issuing authority jointly decide the requirement, and the issuing authority issues the work permit to a competent electrical person to isolate the electrical equipment from the substation. The competent electrical person and the executing authorities install their locks in the multi-lock pad as per color-coding. `

Each lock should be numbered, and the key should be the same number. After locking, the person who installs the lock is the responsible custodian of the key. Electrical maintenance will have to remove the lock lastly after receiving all necessary permits, and the lock should be removed by individual craft after completion of their job.

Handling of electrical equipment or switchgear shall not be done with wet hand or body

When handling electrical equipment or switchgear, it is crucial to ensure that your hands or body are dry to prevent electric shock. Moisture can conduct electricity and increase the risk of electric shock. It is essential to dry your hands and body thoroughly before handling electrical equipment.

Electrical switches or access to them shall not block by any material

Electrical switches or access to them should not be blocked by any material. It is important to ensure that electrical equipment is accessible and free from obstructions to prevent any accidents. Workers should ensure that the electrical equipment and its switches are easily accessible and visible.

Use appropriate PPE while working on electrical equipment

Personal Protective Equipment (PPE) is crucial when working with electrical equipment. The right PPE will depend on the specific job and the risks involved, but common PPE for electrical work includes insulated gloves, safety glasses, and hard hats. PPE can protect workers from electrical hazards and prevent injuries.

Residual Current Device (RCD) or Earth Leakage Circuit Breaker (ELCB)

An RCD or ELCB is an electrical safety device used to protect people from electric shock injuries by sensing the leakage of currents to ground and de-energizing the circuit to prevent the injury. It is important to use these devices to prevent accidents and injuries in the workplace.

Regular inspection and maintenance of electrical equipment

Regular inspection and maintenance of electrical equipment can help identify potential hazards and prevent accidents. This includes checking for signs of wear and tear, such as frayed wires, loose connections, and damaged insulation. It is important to repair or replace faulty equipment promptly to prevent accidents.

Use of proper grounding and bonding

Proper grounding and bonding are essential for electrical safety. Grounding provides a path for electrical current to flow safely to the ground, while bonding ensures that all metal parts of an electrical system are at the same potential. This helps prevent electrical shock and electrocution

Proper use of extension cords and power strips

Improper use of extension cords and power strips can lead to electrical hazards. These devices should only be used temporarily and should be rated for the amount of power being used. Extension cords and power strips should not be overloaded or daisy-chained, and they should be inspected regularly for signs of wear and tear.

Use of warning signs and labels

Warning signs and labels can help alert workers and others to potential electrical hazards. These should be placed in areas where electrical hazards may exist, such as near electrical panels or equipment. Warning signs should be clear, easily visible, and include appropriate safety messages.

Electrical safety training for non-electrical workers

Electrical safety training is not only important for workers who directly work with electrical equipment but also for non-electrical workers who may be working in the vicinity of electrical equipment. These workers should be trained on the potential hazards associated with electrical equipment, the importance of staying clear of electrical equipment and following safety procedures, and the proper use of PPE.

Use of non-conductive tools

When working with electrical equipment, it is important to use non-conductive tools to prevent accidental electrical contact. Non-conductive tools are made from materials that do not conduct electricity, such as fiberglass or plastic. This reduces the risk of electric shock and ensures that the equipment is not accidentally energized.

Emergency response plan

An emergency response plan should be in place in case of an electrical accident. This plan should include procedures for responding to electric shock, electrical fires, and other electrical emergencies. Workers should be trained on the emergency response plan and have access to appropriate first aid equipment.

Electrical safety checklists

Electrical safety checklists can be used to ensure that safety procedures are being followed and to identify potential hazards. These checklists can be used to inspect electrical equipment, check wiring and grounding, verify that lockout/tagout procedures are being followed, and ensure that PPE is being used properly.

Electrical safety audits

Electrical safety audits can help identify potential hazards and ensure that safety controls are being followed. An audit can be conducted by an external consultant or an internal safety team. The audit should include an assessment of electrical equipment, procedures, and training programs.

Don’t hang cloth or any material on electrical equipment

Hanging cloth or other materials on electrical equipment can be hazardous as it can cause equipment to overheat and start a fire. It is important to ensure that electrical equipment is free from obstructions to prevent any accidents. The materials used in electrical work should be non-flammable and non-conductive.

Conclusion

Electricity has become an essential part of modern life, but it can also be dangerous if safety measures are not taken seriously. Electrical hazards, including electrical shock, burns, and fires, can be caused by faulty wiring and equipment, loose connections, lack of grounding, overloading of equipment, and more. To ensure electrical safety, competent and experienced individuals should be trained and certified to perform electrical work, and safety procedures like isolation and multi-lock systems should be implemented. Failure to take safety measures can lead to serious consequences, but proper safety measures can prevent electrical hazards and save lives.

I have been exploring for a bit for any high-quality articles or weblog posts on this sort of area .

Exploring in Yahoo I at last stumbled upon this website.

Reading this information So i am satisfied to convey that I’ve an incredibly excellent uncanny feeling I came upon exactly what

I needed. I so much indubitably will make

sure to don?t disregard this website and give it a look regularly.

You are so cool! I don’t believe I’ve truly read through anything like

that before. So nice to discover somebody with some unique thoughts on this issue.

Seriously.. thanks for starting this up. This web site is one thing that is needed on the internet, someone with a little originality!

Very efficiently written article. It will be supportive to everyone who usess it, including myself. Keep up the good work – i will definitely read more posts.

They’re very helpful

how to make a specific contractor safety plan? give me an example or give me a pattern How to make a specific contractor safety plan?

Amazing blog, I think exploring the world of direct burial wire through these blogs has been enlightening. Clear and concise information for a hassle-free understanding of this essential component in outdoor wiring projects.