1. Introduction

In workplaces where hazardous materials are used, employers have a vital responsibility to ensure the safety and health of their workers. One such hazardous substance that demands attention is 1-Bromopropane (1-BP). This article delves into the hazards, precautions, and occupational safety measures related to 1-BP exposure. We will explore the importance of understanding this chemical, the associated health and safety risks, regulatory requirements, and ways to reduce worker exposure. By following proper guidelines, employers and workers can create a safer working environment and protect their well-being.

2. Understanding 1-Bromopropane

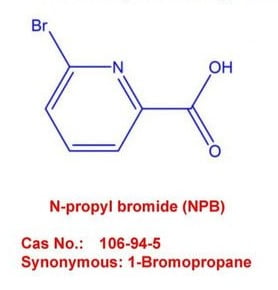

What is 1-Bromopropane?

1-Bromopropane, also known as n-propyl bromide (nPB), is an organic solvent frequently used in various industrial processes such as cleaning, degreasing, adhesive application, and dry cleaning. It is a volatile liquid with a distinctive odor and is commonly found in products like adhesives, aerosol solvents, and cleaning agents.

Uses of 1-Bromopropane

Due to its effectiveness as a solvent, 1-Bromopropane is utilized in several industries for specific applications. Some common uses include:

- Cleaning and degreasing operations

- Adhesive spray applications in various manufacturing processes

- Dry cleaning operations as a solvent replacement for perchloroethylene

3. Hazards Associated with 1-Bromopropane Exposure

Health Hazards

Exposure to 1-Bromopropane can lead to various health issues, both acute and chronic. Some of the health hazards associated with this chemical include:

- Neurological Effects: Workers exposed to 1-Bromopropane may experience neurological symptoms, including headaches, dizziness, and loss of consciousness.

- Respiratory Irritation: Inhalation of 1-Bromopropane vapor can irritate the respiratory system, leading to coughing, shortness of breath, and throat irritation.

- Skin and Eye Irritation: Direct contact with 1-Bromopropane may cause skin irritation and redness. It can also lead to eye irritation and potential damage.

- Reproductive and Developmental Effects: Animal studies suggest that 1-Bromopropane exposure may have adverse effects on reproduction and fetal development.

Other Hazards

- Flammability: 1-Bromopropane is flammable and poses a fire hazard in certain conditions. Proper storage and handling are essential to prevent accidents.

Carcinogenicity

The National Toxicology Program (NTP) has identified 1-Bromopropane as a potential carcinogen based on studies showing increased incidence of lung, large intestine, and skin cancers in rodents exposed to the chemical. While further research is needed to fully understand its carcinogenic properties in humans, precautionary measures are crucial to minimize exposure.

4. Regulatory Requirements and Standards : 1-Bromopropane Safety

OSHA’s Hazard Communication Standard

Under the Occupational Safety and Health Act of 1970, employers are obligated to provide safe and healthy working conditions for their workers. OSHA’s Hazard Communication standard (29 CFR 1910.1200) requires employers to give health and safety information and training to workers potentially exposed to hazardous materials, including 1-BP. Employers must make available copies of Safety Data Sheets (SDS) for 1-BP and train workers to use them. The SDS will note health hazards associated with all ingredients in the product, including 1-BP. Employers must also train workers on health hazards and how to properly use equipment designed to reduce exposures.

NIOSH Recommendations

The National Institute for Occupational Safety and Health (NIOSH) recommends periodic “refresher” training for workers exposed to hazardous materials. NIOSH provides valuable resources for evaluating worker exposures to 1-BP, including sampling results from various industries. Healthcare providers should be aware of potential health effects related to occupational 1-BP exposure and include occupational history in clinical evaluations.

State Plans for Occupational Safety

Twenty-seven states and U.S. territories have their own occupational safety and health state plans approved by OSHA. These state plans include Hazard Communication standards at least as effective as OSHA’s standards, providing protection to workers.

5. Responsibilities of Employers and Workers

Providing Training and Education

Employers must offer comprehensive training and education to workers potentially exposed to 1-Bromopropane. The training should include information on health hazards, proper use of equipment to reduce exposures, and measures to follow in case of exposure.

Evaluating Exposure and Implementing Controls

Employers are responsible for evaluating workplace exposures to 1-BP and implementing appropriate controls to reduce risks. This evaluation may involve measuring 1-BP concentrations in the air and through skin contact. Biological monitoring, such as measuring 1-BP and its metabolites in exposed workers’ urine, can also help assess exposures.

Administrative Controls and Personal Protective Equipment (PPE)

Employers should consider administrative controls, such as reducing the amount of time workers are exposed to 1-BP and minimizing the number of exposed workers

. Additionally, they should limit the use of 1-BP to the smallest amount necessary and ensure that containers are tightly sealed when not in use.

Workers should wear proper personal protective equipment (PPE) to reduce skin exposure to 1-BP. Recommended glove materials for protection against 1-BP are supported polyvinyl alcohol or multiple-layer laminates. When respirators are required, employers must provide and maintain them following OSHA’s Respiratory Protection standard (29 CFR 1910.134).

6. Reducing Worker Exposure

Engineering Controls

Engineering controls are the most effective way to reduce worker exposures to 1-BP. These controls focus on reducing or eliminating the hazard at the source. Some key engineering controls include:

- Isolation: Isolating 1-BP operations can reduce occupational exposure in workers not involved in the process. Employers should consider whether exhaust ventilation is necessary to avoid increased exposure within the isolated area.

- Ventilation: Properly designed and installed ventilation systems, including local exhaust ventilation, can effectively reduce airborne contaminant levels.

- Other Controls: Depending on the work activity, other engineering controls may be helpful. For example, workplaces using vapor degreasing systems should consider automatically-controlled hoists, sliding or rolling covers, and effective cooling coils.

Administrative Controls

Administrative controls are work practices and policies that reduce or prevent exposures to workplace hazards. Some administrative controls to consider in workplaces using 1-BP include:

- Reducing Exposure Time: Limiting the time workers are exposed to 1-BP can help lower their overall exposure.

- Reducing Quantity Used: Employers should purchase, store, and use the smallest amount of 1-BP possible to minimize worker exposure.

- Container Handling: Keeping 1-BP containers tightly closed between uses can help prevent unnecessary exposures.

Worker Exposures Re-evaluation

After implementing engineering controls, employers should periodically re-evaluate worker exposures to ensure that the controls remain effective. This monitoring is essential to maintain a safe working environment.

7. Conclusion

1-Bromopropane presents significant health and safety risks for workers in various industries. Employers must prioritize the implementation of engineering and administrative controls to reduce exposures. Regular re-evaluation and proper use of personal protective equipment can further safeguard workers’ well-being. Compliance with OSHA and NIOSH recommendations, along with strict adherence to regulatory standards, is essential for creating a safe and healthy working environment. By understanding the hazards associated with 1-Bromopropane and following proper precautions, employers and workers can work together to minimize risks and foster a safer workplace.

8. Frequently Asked Questions (FAQs) about 1-Bromopropane Exposure and Safety

1. What is 1-Bromopropane, and where is it commonly used?

1-Bromopropane, also known as n-propyl bromide (nPB), is an organic solvent used in various industrial processes such as cleaning, degreasing, adhesive application, and dry cleaning. It is commonly found in products like adhesives, aerosol solvents, and cleaning agents.

2. What are the health hazards associated with 1-Bromopropane exposure?

Exposure to 1-Bromopropane can lead to various health issues, including neurological effects (headaches, dizziness, loss of consciousness), respiratory irritation (coughing, shortness of breath, throat irritation), skin and eye irritation, and potential reproductive and developmental effects.

3. Is 1-Bromopropane flammable, and how can employers prevent accidents related to it?

Yes, 1-Bromopropane is flammable and can pose a fire hazard under certain conditions. To prevent accidents, employers should ensure proper storage, handling, and use of the chemical. Following safety guidelines and using appropriate containers are essential.

4. What is the regulatory requirement for employers regarding 1-Bromopropane exposure?

Under OSHA’s Hazard Communication Standard (29 CFR 1910.1200), employers are required to provide health and safety information and training to workers potentially exposed to hazardous materials like 1-Bromopropane. This includes making Safety Data Sheets (SDS) available, training workers on health hazards, and proper equipment use.

5. How can employers and workers reduce exposure to 1-Bromopropane?

Employers should implement engineering controls like isolation and proper ventilation to reduce exposure. Administrative controls such as limiting exposure time, reducing the quantity used, and handling containers properly are also crucial. Workers should wear appropriate personal protective equipment (PPE) like supported polyvinyl alcohol gloves and use respirators when necessary.

6. What are the recommended glove materials for protection against 1-Bromopropane?

For protection against 1-Bromopropane, workers should use supported polyvinyl alcohol gloves or multiple-layer laminates.

7. How can employers maintain a safe working environment after implementing controls?

Employers should periodically re-evaluate worker exposures to ensure the effectiveness of controls. Monitoring and assessing worker exposure levels are essential to maintain a safe working environment.

8. How can OSHA and NIOSH assist businesses in ensuring workplace safety regarding 1-Bromopropane?

OSHA offers free and confidential on-site consultations for small and medium-sized businesses to identify workplace hazards and provide compliance advice. Compliance assistance specialists provide general information and educational programs on specific hazards. NIOSH conducts Health Hazard Evaluations (HHEs) upon request to assess employee exposure and health, and provides recommendations to reduce hazards.

9. What are some common uses of 1-Bromopropane in industries?

1-Bromopropane is commonly used in cleaning and degreasing operations, adhesive spray applications in manufacturing processes, and as a solvent replacement for perchloroethylene in dry cleaning operations.

10. What should employers and workers prioritize to create a safer working environment with 1-Bromopropane?

Employers and workers should prioritize implementing engineering and administrative controls, providing proper training and education, and ensuring compliance with OSHA and NIOSH recommendations. Regular re-evaluation of exposures and the use of appropriate personal protective equipment are also crucial to fostering a safer workplace.

9. Some References

- CDC (Centers for Disease Control and Prevention) [2008]. Neurologic illness associated with occupational exposure to the solvent 1-Bromopropane—New Jersey and Pennsylvania (2007–2008). MMWR 57(48):1300-1302.

- NIOSH [2000]. NIOSH health hazard evaluation report: Trilithic, Inc.; Indianapolis, IN. National Institute for Occupational Safety and Health, HETA No. 2000-0233-2845

- NIOSH [2002a]. NIOSH health hazard evaluation report: Custom Products, Inc.; Mooresville, NC. National Institute for Occupational Safety and Health, HETA No. 98-0153-2883

- NIOSH [2002b]. NIOSH health hazard evaluation report: STN Cushion Company; Thomasville, NC. National Institute for Occupational Safety and Health, HETA No. 2000-0410-2891

- NIOSH [2003]. NIOSH health hazard evaluation report: Marx Industries, Inc.; Sawmills, NC. Cincinnati, OH: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, NIOSH HETA Report No. 99-0260-2906

Disclaimer: This article serves as an informational guide and should not be considered a substitute for professional advice. Employers and workers should always consult relevant regulatory authorities and seek expert guidance to ensure compliance with the latest safety standards and best practices.